Terminating Cover Crops

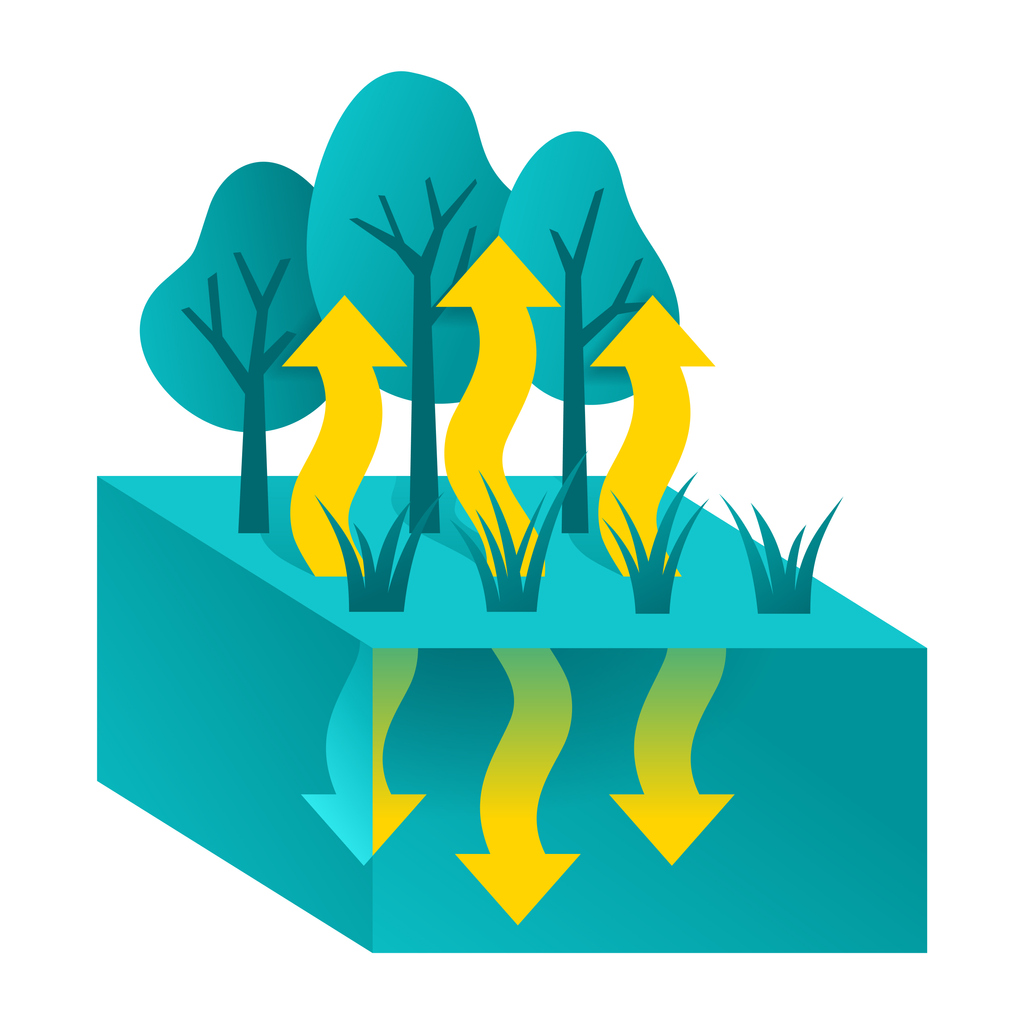

As planting season is partially delayed in some areas due to wet weather, farmers are wondering when and how to terminate their cover crops. If soils are wet, a growing cover crop helps dry out soil through evapotranspiration. Crop water use, also known as evapotranspiration (ET), represents soil evaporation and the water used by a crop for growth (transpiration). Transpiration is the water transpired or lost to the atmosphere from small openings on the leaf surfaces. Evaporation is the water evaporated or lost from the wet soil and plant surfaces. When a crop reaches full cover, approximately 95 percent of ET is due to transpiration and evaporation from the crop canopy at full sunlight.

About 97-99% of water absorbed by plant roots is lost to transpiration. Most plants have a total transpiration of 440 to 2,200 pounds of water per pound of plant growth. Cool season grasses like rye have a higher transpiration rate than warm season grasses like corn. When cereal rye is at its peak spring growth, a very rough estimate is 0.1-0.2 inches of soil water removed per day. Factors like crop stand (100% in this example, 3 feet tall), soil moisture (assumed to be full capacity), warm temperatures, high light, moderate to high wind speed, and humidity all create higher evapotranspiration rates. If soils are wet, letting a cover crop grow can speed up soil drying so the main crop can be planted quicker.

Cover crop roots also increase soil structural stability (better traction), so planting green into a standing cover crop can be a viable option for no-till farmers. Terminate cover crops quickly if the soil is getting too dry. Cover crops are commonly terminated with herbicides. For grasses, glyphosate kills most grasses and saflufenacil (Sharpen®) and 2-4D are effective on most legumes and or clovers. Systemic herbicides, such as glyphosate, are most successful when applied on warm, sunny days when plants are actively growing. Termination treatments should be applied before the boot stage of grasses. A follow up POST treatment of growth regulator herbicide and/or glyphosate in corn and certain soybean trait systems can complete covers that partially survive a burndown treatment (Mark Loux, OSU Weed Specialist).

Crimper crop rollers can terminate cover crops naturally, reducing herbicide application. Selecting the right cover crop to crimp and timing are critical for good crimping results. Cereal rye, oats, triticale, and wheat can be crimped effectively when the head is fully emerged. Avoid trying to crimp soft flexible plants like annual ryegrass or perennials like red clover or alfalfa. For legumes; hairy vetch, winter peas, cowpeas, Balansa and crimson clovers have been successfully terminated by crimping. The best time to crimp legumes and clovers is when they start to bloom.

Cereal rye is the most common cover crop crimped, either before or after planting soybeans. If crimping before planting, make sure you plant in the same direction and the crimper should be the same width as the planter. Planting across crimped cover crops may cause twisting, binding, wrapping, and hair pinning to occur. Planting green and then crimping at a later date works well. Soybeans can be crimped up to 4-5 inches tall and corn up to V4. Be careful not to crimp when soybean cotyledons are emerging. Clipping off cotyledons causes soybeans to die Once 1-2 trifoliate soybean leaves emerge, it is generally safe to crimp.

Crop rollers can crimp about 1 acre per foot of implement when traveling 8-10 mph so a 15- footer crimps 15 acres/hour and a 30-footer, 30 acres/hour. When conditions are dry, adding water or oil to the drum reduces bouncing and increases crimping effectiveness. Drain the drum before winter to avoid cracking the drum. Crimping effectiveness may be improved by driving at a slight angle. Sometimes there is a slight elevation difference on the row compared to the area between the rows, and driving at an angle allows the crimper to roll across the row for a better crimp.

For safety, make sure you have a big enough tractor to handle the weight and to easily lift and turn on the ends. On 3-pt hitch models, extra weight may be needed on front of the tractor to prevent the front wheels from coming off the ground. On trailed crimpers, hydraulic tractor lift is the most limiting factor. It takes very tittle horsepower to roll the crimper but it takes some power to lift it up on the ends. If you leave the crimper down while turning, its hard on the equipment and drags up soils as it turns. Watch out for ground hog holes, sink holes, fences, trees, light poles and turning too fast.